Note

24/12/2024: "On-screen measurement" moved from "Quality Alerts". "螢幕計量"從"質量提示"搬過來。

27/9/2024: Section on query list expanded.

26/2/2023: Some taking-off fundamentals added.

20/2/2023: Revised.

23/3/2020: Page on query list merged into here.

27/7/2019: Partly split to different pages.

23/12/2014: Moved from wiki.

Processes 程序

-

The traditional manual processes of measurement and billing are:

- Take-off (measure dimensions)

- Square (calculate products and sums)

- Transfer (carry forward quantities)

- Abstract (summarize)

- Bill (describe and list)

- Transfer (bring forward quantities).

- Concurrent with the measurement and billing, query lists should be issued.

- After the transferring process, there are the following processes:

- Edit (the written draft BQ)

- Type

- Read over

- Clear Drawings, Specification and Preambles

- Bulk check

- Adjust

- Edit finally

- Correct finally

- Read quantities

- Photocopy

- Check pages

- Bind

- Pre-tender Estimate

- Issue Tender Addendum.

- With the use of BQ production software, squaring, transferring, abstracting and billing can be combined by linking the dimensions with the final BQ items.

- The dimension by dimension taking off may be replaced with CAD or BIM measurement.

- However, the processes still exist implicitly though taking a different form.

Taking-off 度數/計量

-

The process of measuring the quantities of items of work is called "taking-off" or "quantity-take-off" or "QTO" whereby the dimensions of the items of work are (traditionally) written down on a dimension sheet.

- Person(s) taking-off are called "Taker(s)-off".

Some taking-off fundamentals

(section added, 26/3/2023)

- Clarify which Method of Measurement:

- The Method of Measurement (more properly “rules”) to be used or which has been used should be clarified during the briefing session upon commencement of taking-off

- For pre-contract cost estimates, the Method of Measurement will be determined by the Consultants, and the quantities are usually approximate and relative items are grouped together to save time

- For Pricing Schedules with quantities provided by the Consultants, the Method of Measurement should be stated

- For new works, the Method of Measurement will be prescribed as to follow the Hong Kong Standard Method of Measurement of Building Works – Fourth Edition 2005 (“HKSMM4”) or Fourth Edition Revised 2018 ("HKSMM4R") published by The Hong Kong Institute of Surveyors

- For Government term maintenance contracts, they use Architectural Services Department Schedule of Rates for Term Contracts for Building Works 2019 Edition: (https://www.archsd.gov.hk/media/publications-publicity/schedule-of-rates/sor2019_vol_1_bw_2.pdf and https://www.archsd.gov.hk/media/publications-publicity/schedule-of-rates/sor2019_vol_2_bs_2.pdf), which prescribe the Method of Measurement

- The standard methods of measurement describe what should be measured and what can be deemed to be included in the rates and prices and need not be measured

- For Pricing Schedules with quantities to be inserted by the Tenderers, the Method of Measurement may be prescribed by the Consultants but usually it is left to the Tenderers

- The Tenderers may follow the standard Method of Measurement or may simplify or deviate

- In any case, the method used by the Tenderers in the Pricing Schedule should be used for pricing variations and remeasured provisional quantities.

- Read Method of Measurement:

- Inexperienced Takers-off should read the relevant sections of the prescribed Method of Measurement before taking-off

- Experienced Takers-off should review the relevant sections of the prescribed Method of Measurement from time to time during the course of taking-off

- Upon completion of taking-off, all Takers-off should take a final review of the prescribed Method of Measurement to ensure that there are no missing items to be measured.

- Pay extra attention to how to treat:

- Wastage (not measured)

- Gross or net measurement

- Deductions for openings (small voids or openings not deducted, such as those not exceeding 0.50 m2 or 1.00 m2 or 0.50 m3 depending on the type of work)

- Laps and intersections

- Working space for excavation (0.25 m or 0.60 m depending on the height of formwork below ground)

- Slopes of excavated spaces (designed or restricted excavation profiles)

- Staging or ranging where items can be measured together or separately (excavation depth below ground in successive stages of 1.50 m, soffit formwork and ceiling finishes heights above floor not exceeding 3.50 m high, then in 1.50 m stages, etc.)

- Sloping work (from horizontal) / slanting work (from vertical)

- Circular work (usually measured separately)

- Extra over items (principal items overlapping with the extra over items not deducted in the quantities, but to be considered in the unit rates, e.g., pipe bends, tees, etc.)

- Tenderers not strictly following any standard Method of Measurement may follow the above treatment as common practice.

- Measure net quantities:

- Measure all work net as fixed in position, unless otherwise stated

- This is a very important principle

- If there is no prescribed Method of Measurement, at least state that “all work is to be measured its net quantity as fixed in position with no allowance for wastage and, in case of work measured superficially, for laps, unless otherwise stated”

- Work which are “superficial” (as compared to “linear” or “cubic”) and have laps not to be measured are wire mesh, waterproof layers, pitched roof tiling, etc.

- Work which are linear and have laps to be measured are reinforcement bars, door frames, skirtings, etc.

- Deduct voids:

- Voids (openings and wants) smaller than the sizes specified in the SMM are not to be deducted

- However, this refers to voids detached from the boundaries of the space measured

- Voids caused by projections from the boundary of the space measured are always deducted:

- Costs held to be included in items (HKSMM4 and 4R):

- Labour and all costs in connection therewith

- Materials, goods and all costs in connection therewith (e.g., conveyance, delivery, unloading, storing, returning packings, handling, hoisting and lowering)

- Fitting and fixing materials and goods in positions

- Use of plant

- All cutting and waste

- Establishment charges, overhead charges and profit.

- Units of measurement (HKSMM4 and 4R):

- Items given by weight - kilograms

- Items given cube - cubic metres

- Items given super - square metres

- Items given run - linear metres

- Items enumerated - number of sets, as applicable

- Items given by time - Days or Hours, with definitions stated

- Dimensions used in calculations - rounded off to the nearest 10 mm.

- Units of billing (HKSMM4 and 4R):

- Billing BQ:

- Rounded to the nearest whole unit

- Subject to a minimum of 1 if more than 0

- Billing variations and remeasurement:

- Rounded to the nearest 0.1 for m, m2, m3

- Rounded to the nearest 1 for kg

- Applicable to omissions or additions

- Quantity less than 1 but billed as 1 in the original contract to be omitted as 1 if the quantity is not done

- Order of dimensions in BQ or dimension sheets:

- Generally, in the sequence of length, width and height.

- Billing BQ:

- Ranges:

- When a range of widths, heights, depths, etc. is given in the item description in a Pricing Schedule, “A – B” usually means “exceeding A but not exceeding B”.

- A - B = exceeding A but not exceeding B = "> A but <= B".

- Pipe and tubing (HKSMM4 and HKSMM4R):

- Pipe size: to be described by nominal sizes

- HKSMM4 pipe size groups for the purposes of painting (all measured run):

- pipes <= 50 mm diameters

- pipes 50 - 100 mm diameters

- pipes > 110 mm diameters, pipe size stated

- HKSMM4R pipe size groups for the purposes of painting:

- pipes <= 300 mm girth (measured run)

- pipes > 300 mm girth (measured super).

- Circular work (HKSMM4 and HKSMM4R):

- No grouping by radius.

- Prime cost rates (P.C. Rates):

- Where a prime cost rate (P.C. rate) is included for a component in the description of an item in the Bills of Quantities, the prime cost rate is either (a) for the material cost of that component delivered to site only and the Contractor shall allow in addition for all waste, fixing, all ancillary materials required for fixing such as mortar for bedding and jointing and all other similar items of a like nature, and for profits and overheads, or (b) for the cost of supply and installation or application of the component (such as specialist suspended ceilings or finishes) as charged by a domestic sub-contractor, and the Contractor shall allow for his own profits and overheads.

- In the settlement of the Final Account, the rate for the item will be adjusted by the net difference between the prime cost rate and the actual unit cost and will be applied to the nett quantity of the component measured as fixed, installed or applied in position, exclusive of wastage.

- Provisional Sum:

- A sum provided for work or for costs which cannot be entirely foreseen, defined or detailed at the time the tendering documents are issued.

- In the settlement of the Final Account, the provisional sum will be omitted from, and the actual expenditure added to the Contract Sum.

- Prime Cost Sum:

- A sum provided for work or for services to be executed by a Nominated Sub-Contractor or for materials or goods to be obtained from a Nominated Supplier. Such sum shall be deemed to be exclusive of any profit or attendance required by the Contractor and provision shall be made for the addition thereof.

- In the settlement of the Final Account, the Prime Cost Sum will be omitted from, and the actual expenditure added to the Contract Sum.

- The Contractor’s profit is to be allowed as a percentage of the Prime Cost Sum. The same percentage will be applied to the final expenditure of the Prime Cost Sum in the settlement of the Final Account.

- The Contractor’s attendance is to be allowed as a lump sum not to be adjusted in the settlement of the Final Account, but if the Prime Cost Sum is not expended at all, then the lump sum will be omitted.

- Work to be specifically described as such:

- Work under reservoir, river or sea water

- Work in compressed air

- Work outside the curtilage of the Site

- Work in existing building

- Temporary works.

Long hand manual dimension sheets (school arithmetic) 長式手工計算紙

- Calculations may be set out in the usual arithmetical form:

計算可如一般的算式列出: - This uses less paper, but is difficult to trace, compare and inspect for errors.

這樣非常省紙,但難於對比和檢查錯誤。

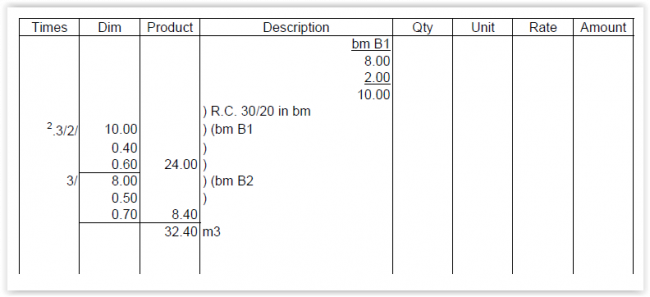

Traditional manual dimension sheets

- Traditional dimension sheets used to take-off quantities take the following form (as seen in textbooks):

- Dimensions are set in vertical stack, in the order of length, width and breadth.

- A line is used to separate each set of dimensions.

- Timesings are written on the left column.

- In this column, "/" means multiply, not divide.

- ". " means add, an action called "dotted on".

- The products are given in the right column.

- The descriptions are very much abbreviated to reduce writing.

- The calculation in the description column is the build-up of one of the dimensions.

- It is called a "waste calculation" or "side-cast".

- The annotations "bm B1", "bm B2" in the description column are to identify the locations of sets of dimensions.

- This action is called "sign-posting".

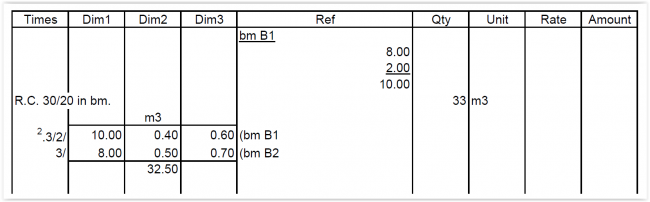

Another kind of manual dimension sheets

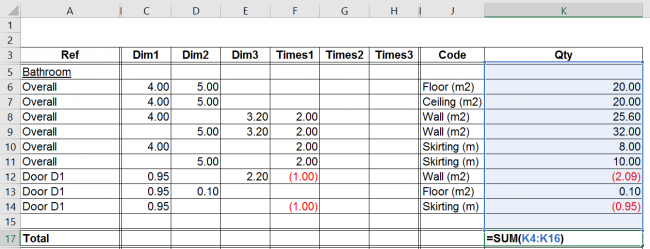

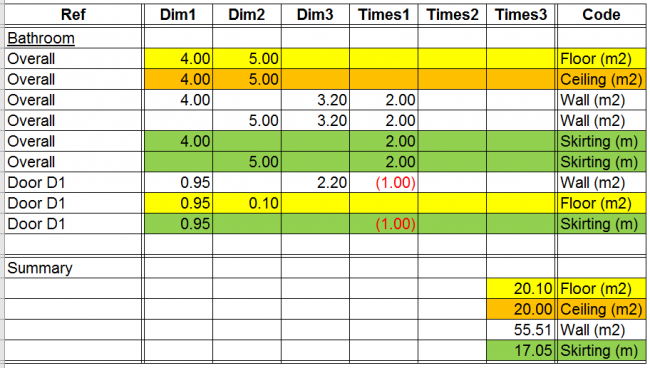

- Another kind of dimension sheets is to lay out the dimensions horizontally as follows:

- The products of dimensions are not written one by one.

- Only the total of the products is entered at the bottom.

- This is made feasible with the popular use of electronic calculators with memory function.

- It would be faster to calculate once more than write down all the products before summing up.

- Laying out the dimensions horizontally actually improve the presentation and make comparison of dimensions easier.

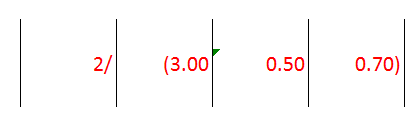

- Deductions are indicated by putting brackets to enclose the set of dimensions, and write them in red:

- The right hand columns can be utilized as rate and extension columns for final account purposes.

Manual taking-off schedules 計算表

- Dimension sheets require descriptions against group of dimensions.

- To reduce writing descriptions, dimensions of all quantities of the same item should be measured in one go and this requires greater experience.

- For measurement of group of items which have a lot of inter-related dimensions, use of dimension sheets would be cumbersome.

- A taking-off schedule would be preferred.

- The schedule sets out inter-related dimensions and items in a systematic manner.

- This reduces the need to repeat descriptions.

- This enables measurement of more than one items at the same time.

- This makes comparison and identification of errors easier.

- The following schedule for the same dimensions above measures concrete and formwork at the same time sharing the same set of dimensions:

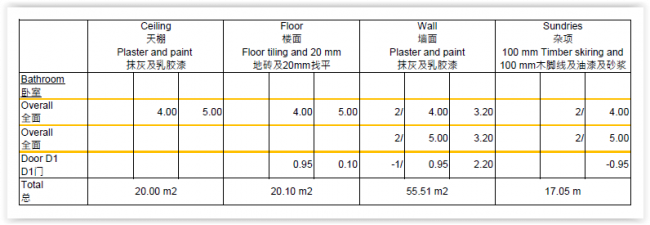

下列的計算表,把共用原始尺寸的項目並列一起計算,較容易看到互相的關係: - The following schedule puts all finishes items sharing the same primary dimensions together and enables easier understanding of their inter-relationship:

- "/" = Times.

乘 - () = Deduct.

扣減

- Deductions are written in red or, if black and white photocopying is anticipated, marked with a minus sign or with brackets.

- The number of columns for each set of dimensions is flexible.

- For items measured Cube, four columns are allocated.

欄數可加減,立方項用4欄。 - Since the width of a sheet of paper is limited, a column needs to be shared by more than one item, e.g. two types of floor finishes, and colouring of the boxes is used to distinguish dimensions of different items.

因紙寬有限,可用顏色在同一組欄下表示不同的專案,加總時按顏色分開加。

Squaring 運算

- The process of calculating the products of dimensions and totals on dimension sheets and taking-off schedules is called squaring.

- The person is called a "Squarer" or "Comptometer".

- To ensure correctness, each calculated total entered by a Squarer must be counter-checked and initialled by another Squarer.

- Squaring is a tedious process even with the help of electronic calculators before the use of computer spreadsheets or BQ production software.

- 計算紙或計算表列式後要運算。

- 用普通計算器及人手計算的要另外有人覆核並簽署。

- 用電子計算器及軟體計算的,要建立覆核公式覆核。

On-screen measurement 螢幕計量

- Do not rely too much on on-screen measurement of cad or pdf files because there is no record of what have been measured and no detailed breakdown.

不要太依賴用cad或pdf檔 在螢幕計工程量,因計了那裡都無紀錄,又無細數。 - Use hardcopy and dimensions to measure or use scale where necessary in case of no dimensions.

用紙張件及標示尺寸計算或在無標示尺寸時用尺量。 -

Colour on the hardcopy to indicate extent measured.

在紙張件著色識認計算了那裡。(Written on 4/11/2015 and moved from "Quality Alerts"; 4/11/2015初寫,從"質量提示"搬過來, 24/12/2024)

Abstracting 匯總

- Dimension sheets or taking-off schedules measure more than one item on the same sheet or schedule.

- The same BQ item may appear on more than one sheet or schedule.

- Therefore, it is necessary to collate the individual quantities of the same BQ item appearing on more than one sheet or schedule together to arrive at the grand total of the item.

- A summary schedule is used to bring together the individual quantities to add up the grand total.

- The process of transferring the individual quantities from dimension sheets or taking-off schedules to the summary schedule is called "abstracting".

- 計算紙或計算表運算後要匯總。

- 工程量清單某分項數量可能要由幾張計算紙或計算表得出,所以要匯總。

Billing 列單

- The items in the summary schedule are then transferred to the draft BQ pages in the correct sequence with the descriptions expanded in full without abbreviations.

- This process is called "billing" and requires experienced Surveyors to do.

- The whole process from squaring to billing is called "working up".

Transferring 轉移

- Information is transferred from the dimension sheets or taking-off schedules to the summary schedule to the draft BQ.

- Every transfer of descriptions, units and quantities has to be counter-checked by another Surveyor.

- The actions are called "transferring" and "transfer-checking" or "to check transfer".

- 從計算紙或計算表轉移到匯總卡後要他人覆核簽署。

- 從那裡來往、往那裡去,都要寫。

Cut and shuffle 洗牌式

- Abstracting and working up are tedious processes involving a lot of transferring and transfer checking.

- More movements of information from one to another will increase the chances of making errors.

- A method has been devised whereby:

- each dimension sheet only contains one item

- when the taking-off is finished, dimension sheets of the same BQ item are collated and stapled together

- if taking-off schedules are used, the totals are transferred to the respective dimension sheets

- squaring is done to obtain the grand total which is written on the front dimension sheet

- short descriptions are expanded to full descriptions on the front dimension sheets

- the dimension sheets are then shuffled according to the intended BQ sequence

- headings are added as appropriate

- BQ is directly typed from the dimension sheets which have headings, descriptions, unit and total quantities.

- The number of processes is greatly reduced.

- A drawback of this system is that when the dimension sheets are shuffled, the original sequence and logic of measurement are lost.

- Therefore, when the system was originally invented, the dimension sheets came together in 4 on one sheet of paper and were backed with a self impressed carbon copy.

- After taking-off in a logical sequence, the front sheet (A4 size) was taken out and cut into 4 vertical pieces or 2 horizontal pieces which were shuffled and sorted with other sheets.

- The carbon copy was kept in the original sequence to facilitate future reference.

- 每一個工程量清單分項都有一張卡,可以A4紙分為二或四。

- 每卡都寫上工程量清單分項的工程合同名稱、卡號、清單號、分項說明、單位、計算紙或計算表編號、搬來數量、匯總數量。

- 格式例:

-

-

- 匯總卡可按清單分項次序自由排序。

- 排序後要運算每卡總數,寫在上部。

- 總數由他人覆核。

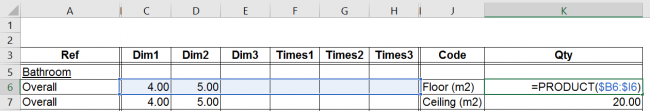

Using Excel

- Electronic spreadsheet software like Excel can be used as dimension sheets or taking-off schedules.

- However, using electronic spreadsheets to imitate dimension sheets would require the defining of many calculation formulae.

- If the formulae cannot be consistently defined to enable copy-and-paste repeatedly, the defining process will be tedious and prone to errors.

- Using electronic spreadsheets to imitate taking-off schedules is more suitable.

- However, taking-off schedules when put into an Excel worksheet will become too wide to view on screen.

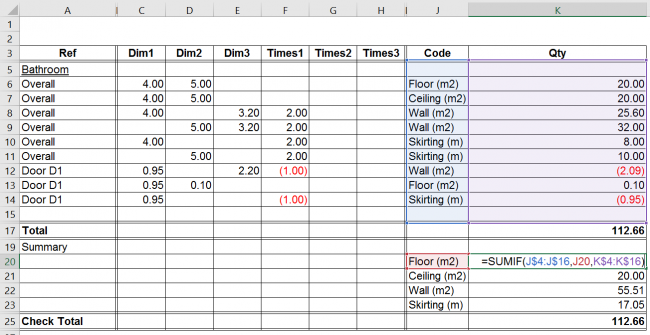

- It is suggested to set out the dimensions using less columns in the following manner:|

- Instead of adding columns for different items of work, codes are used to represent items row by row.

- Note that Columns B and I and Rows 4, 16, 18, 24 and 26 have been reduced to narrow widths and heights respectively.

- They will be used as the boundaries of ranges of columns or rows used in formulae such that any insertion of columns or rows within the boundaries would not go outside the defined ranges unexpectedly.

- The PRODUCT(range) function has been used in the following tables to calculate the Qty:

- Note that the range is from the narrow Column B to Column I.

- Within the defined range, empty cells are regarded as having value 1.

- “$” is used to anchor the columns in case the Qty column is copied to some other places without the intention to change the referred columns.

- The SUM(range) function has been used in the following table to calculate the total:

- Note that the range is from the narrow Row 4 to Row 16.

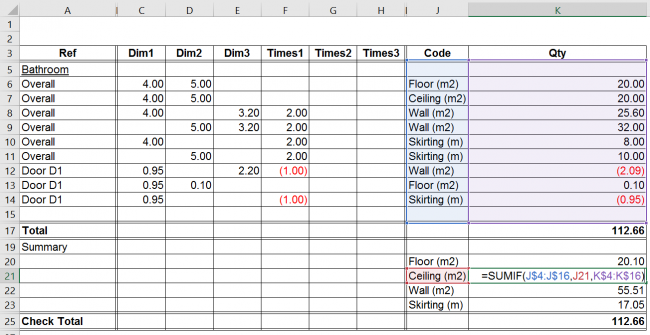

- The SUMIF(range to check, criteria, range to sum if criteria matched) function has been used in the following table to calculate the total qty per code:

- In the above table, if a cell value in the range to check is equal to the criteria, e.g. a cell value in the range to check “J$4:J$16” matches the value of cell J20, then the cell value on the same row in “K$4:K$16” will be added to the sum.

- “$” has been used to anchor the rows such that when the formula is copied down to other rows, the defined range will not change as shown in the following table:

- Column J may need to be anchored as well if the same formula is copied sideway to other columns.

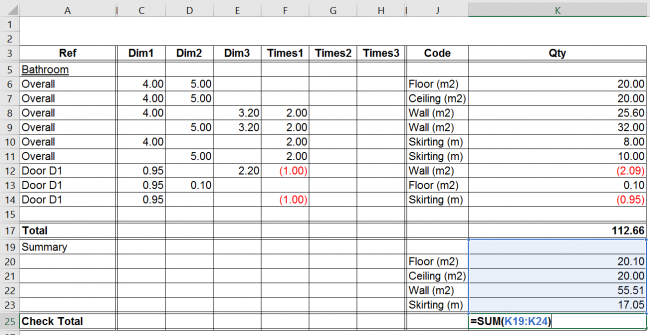

- To ensure that the sum of all sub-totals equal to the grand total, another check total should be calculated.

- Note that in the following table, the upper boundary of the range to sum is Row 19 the heading row instead of Row 18 the narrow row:

- This serves the same purposes of bounding the ranges.

- An advantage is that Rows 19 to 25 can be moved to elsewhere independent of Row 18.

- It is important that insertion must be by rows or columns not by cells, and copying and pasting of cell values to other places are preferred to cutting and pasting, to avoid corrupting the formulae.

- Formulae must be refreshed by copying the correct ones to the other corresponding cells.

- There must always be a double-check of the totals using alternative method or formula to ensure no omission or duplication.

(positions of images relative to items adjusted, 20/2/2023)

Paper based table

- When doing quick measurement without using Excel, users may use coloured rows to highlight rows to be added using manual calculator to obtain the total:

- Individual qty per row may be skipped to save time.

- It is important to calculate the totals twice to ensure no error.

(position of image relative to item adjusted, 20/2/2023)

Direct billing

- With substantial portion of taking-off information given in taking-off schedules in tabulated and inter-related manner, the portion of taking-off directly on dimension sheets is greatly reduced.

- The need for carbon copy to keep the original taking-off sequence and logic is also reduced.

- "Cut" is also no longer required, one independent sheet can be used for one BQ item, leaving the "shuffle" behind.

- Taking-off directly onto these dimension sheets which can be shuffled immediately for billing is called "direct billing".

Query list 編標問卷

- During the course of BQ production, there is bound to be uncertainty of information either in respect of the project particulars or in respect of the Drawings and Specification.

編寫工程量清單時,常會碰到工程細節、圖紙或工料規範有不清楚的地方 - Clarify with the Architects or Engineers using telephone conversation or email.

先以電話或電郵詢問設計單位(建築師和工程師) - Write down the answers obtained on a query list.

用“編標問卷”書面記錄答案 - Make reasonable and confident assumptions on the query list prior to receipt of answers.

未有答案前,可把有信心的合理假設寫在問卷上 - Refer to the following sample form:

參考以下格式例:-

-

- To avoid grammatical mistakes and to reduce the subsequent time to make corrections, write the queries in note form which is still understandable instead of long complete sentences, particularly when writing queries with assumed answers, if they when read together are sufficient to make sensible and complete meaning.

為了避免語法錯誤並減少隨後更正的時間,可以用足以理解的短語,而不是完整的長句,特別是在寫問題附有假設答案時,如果它們一起閱讀已足以產生合理且完整的含義 - Dispatch the query list from time to time to the Architects or Engineers for answering outstanding queries or confirming answered queries and for record.

定期發出問卷以便取得未有的答案或確定已有的答案及做為記錄 - Chase for the return of the query list with answers within a reasonable time.

跟進在合理時間之內有回覆 - Reflect the final answers in the Bills of Quantities.

把最後的答案在工程量清單反映 - Request the Architects and Engineers to revise the Tender Drawings and Specification to match the answers on the query lists, and issue them to the tenderers.

請建築師和工程師修改招標圖紙和規範,以符合編標問卷上的答案,並發送給投標人。 - If the revisions are not made before return of tenders, they should be made in the post contract stage, and explanation would need to be given that the revisions have been considered in the Bills of Quantities. The Contractors may want to see proof, and this would be troublesome. The earlier the better,

如果在回標之前沒有進行修改,則應在施工階段修改,並應說明修改已在工程量清單中考慮。承包商可能想查看證據,這會很麻煩。越早越好。 - According to SFBC 2015 (with quantities), the Contractor shall carry out the Works according to the Drawings and Specification without being strictly obliged to counter-check against the Bills of Quantities. Non revision of the Drawings and Specification may mean that the Contractor may carry out the Works according to the incorrect Drawings and Specification though the Bills of Quantities have been measured correctly.

根據 SFBC 2015(含工程量),承包商應根據圖紙和規範施工,而無被嚴格要求對照工程量清單進行覆核。未修訂圖紙和規範可能意味著承包商可能會根據不正確的圖紙和規範施工,儘管工程量清單已正確計算了。 - The Architect and Engineers may not revise the Drawings and Specification readily. A solution is to re-draft the answered query lists to final and simple statements of revisions and issue them to the Architect, Engineers and Contractor for attention to avoid following the incorrect Drawings and Specification.

建築師和工程師或不會爽快修改圖紙和規範。解決方案之一是將已回答的編標問卷改為最終和簡單的修訂說明,並將其分發給建築師、工程師和承包商以引起注意,以避免遵循不正確的圖紙和規範。 - There can be various kinds of queries during the tender documentation and tendering process until contract award, and they can be called by different names like "tender queries" raised by the tenderers, and "post tender questionnaires" after return of tenders. It would avoid doubt if the query lists here are re-named "Tender Documentation Query Lists".

在編招標文件和招標過程中直至授予合同前,可能會出現各種提問,這些提問可以有不同的名稱,如投標人提出的“投標問卷”,及回標後的“詢標問卷”。如果此處的英文名稱“Query List (問卷)”改為"Tender Documentation Query List (編標問卷)" ,可避免混淆。 - Note that a query list can contain more than one query. Query List No. 1 should mean the first query list, not the first query. Do not write "Queries List No. 1".

請注意,一份編標問卷可以包含多個問題。“編標問卷一”應該表示第一份問卷,而不是第一個問題。英文應適當的使用單數和複數。

(Item 6 revised, and items 10 1o 15 added, 27/9/2024)